Samuel Oldknow (5 Oct 1756-18 Sep 1828) founded his lime-burning business at Marple in the early 1790s and it was certainly operational by Aug 1796 when the Peak Forest Tramway and the Upper Peak Forest Canal opened for trade. There were five kilns in the battery, which were probably all built between 1796 and 1799. Oldknow had the battery designed in such a way that it resembled a Gothic church in order not to spoil the view from his home at nearby Mellor Lodge. The structure incorporated a number of dwellings, ostensibly for the use of workers operating the kilns, but census returns show that this was by no means the case. People with a range of occupations lived there, such as coal miners, boatmen and cotton mill operatives. The 1881 census records nine dwellings and some inhabitants were buried in the graveyard of All Saints, Marple. It is uncertain as to whether Oldknow had the dwellings included in the original construction or whether they were added at a later stage.

Nonetheless, Oldknow quickly lost his enthusiasm for burning (calcining) lime and in 1798 he leased the battery to a consortium of four businessmen, Joseph Heathcote Senior, Joseph Heathcote Junior, William Fletcher and Anthony Ashmore. Later, Oldknow was still not satisfied with the circumstances he was in, blaming the situation on the effects of the Napoleonic War, and as a result he leased the battery again in 1811 to Messrs Wright and Brown (Nathaniel Wright and Thomas Brown, the latter being the surveyor and resident engineer for the construction of the Peak Forest Canal). It is not know for how long these two business partners operated the kilns but by 1834, six years after Oldknow's death, it was being run by John Clayton & Company, John Clayton being Oldknow's half brother and successor.

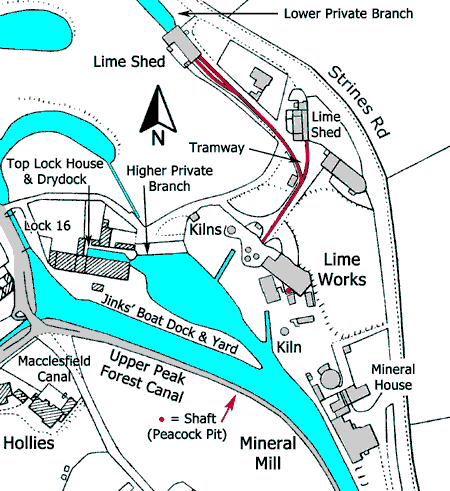

Supplies of limestone and coal destined for the kilns were brought along the Upper Peak Forest Canal. Limestone came from the quarries at Dove Holes via the Peak Forest Tramway and Bugsworth Basin while coal came from several pits alongside the canal and for a while from a pit inside the lime works. The kiln heads were accessed by the Higher Private Branch, which opened into a small basin known today as Marple Basin. Here there were two short canal arms, the most westerly of which enabled boats to come close to four of the kilns, while the easterly arm came close to the isolated fifth kiln.

At the foot of the kilns there was an arrangement of tramway sidings that enabled burnt lime (quicklime) to be transported a short distance to two lime sheds where the contents of the waggons could be transhipped undercover. One of these sheds spanned the head of the Lower Private Branch to enable two boats at a time to be loaded. Once full and sheeted over with tarpaulin, boats made their way along the branch to join the main line of the canal at Posset Bridge below lock 13. The other shed enabled carts to be loaded undercover and, similarly, these were then sheeted over with tarpaulin before they left by road.

The burnt lime had many uses, typically by farmers as a soil conditioner, the construction industry, the chemical industry and the textile industry.

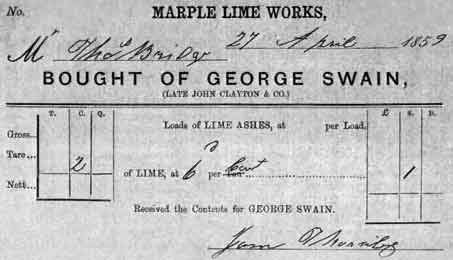

By 1858, the lime works was being run by George Swain who described himself as the successor to John Clayton & Co. George Swain ran the works until c.1864 when he relinquished the lease to become the landlord of the nearby Navigation Inn. Between c.1864 and 1875 it is uncertain as to who ran the works but it will be seen later that Jesse Tymm was becoming increasingly influential during this period. Certainly by 1875 he was in control of the business, possibly with the assistance of his brother, Wright, who seemed to a junior partner in the business.

Swain Ticket, dated 27 Apr 1859.

2 cwt of lime at 6d per cwt = 1s 0d.

Left: Marple Lime Kilns (aka Oldknow's Lime Kilns), early 20th century.

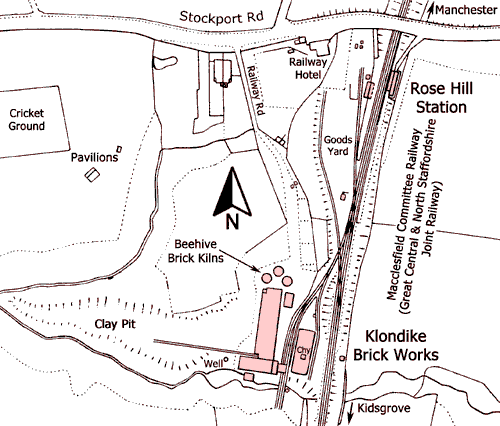

Right: Map of Marple Lime Works and Mineral Mill, 1898.

The above map shows the relative positions of the Lime Works, Mineral Mill, Mineral Mill House and the boat dock and yard belonging to the Jinks family of boatbuilders of Top Lock House.

The tramway sidings from the foot of the kilns connected to a lime shed that spanned the head of the Lower Private Branch, where two boats could be loaded, and the other connected to a lime shed where carts could be loaded. These sidings would once have joined the Marple Tramway that connected the upper and lower levels of the Peak Forest Canal together while Marple Locks were under construction. As a result of severe financial difficulties it was not until the autumn of 1805 that Marple Locks finally opened throughout and Marple Tramway closed in February 1807.

In 1860 a coal shaft was sunk alongside the lime kilns in order to reduce the transport of coal to an absolute minimum. The shaft was 38-yards deep and it accessed the Yard Mine (coal seam). This became known as Peacock Pit (aka Marple Colliery) but the origin of the name ‘Peacock Pit’ is obscure. It is possible that it was originally thought to be the same seam as the Peacock Mine in Hyde that was worked in both Hyde Lane Colliery and the nearby Peacock Pit.

By 1875, Jesse Tymm was in control of lime burning and coal mining at Marple and his brother, Wright, was a junior partner in the business. In its final years only around 10 or 12 coal miners were employed there and it closed in October 1893.

Marple Lime Kilns are scheduled under the Ancient Monuments and Archaeological Areas Act 1979, List Entry No. 1001955. The walling of Marple Lime Kilns is Grade II listed, List Entry No. 1242485. The walling consists of four concaved bays which act as a retaining wall and gave access to the kilns which were tunnelled into the hillside. Bays 1 and 2 have semi-circular headed openings (now blocked) which formerly had two tiers of Gothic lights. Bay 3 has a blocked semi-elliptical headed opening. The lower arches in each bay are now obscured by raised ground level.

The lime kilns are on Historic England's Heritage at Risk Register because they are generally unsatisfactory with major localised problems due to scrub and tree growth.

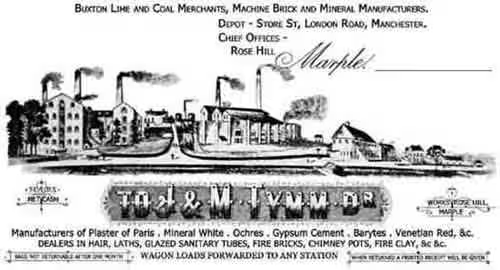

Products of J & M Tymm

The billhead of J & M Tymm shows that the firm was principally involved in trading lime and coal as well as the manufacture of machine-made bricks and a range of minerals. The minerals listed included

Gypsum, Plaster of Paris, Ochres, Barytes, Venetian Red and Mineral White. In addition to this, they were dealers in hair, laths, glazed sanitary tubes, firebricks, chimney pots and fire clay.

Barytes (barium sulphate) was available from Derbyshire, particularly in association with veins of lead ore, while Venetian Red (ferric oxide) was made by calcining copperas (ferrous sulphate) in the

presence of lime. Plaster of Paris was produced by calcining gypsum. Mineral White was believed to be a form of gypsum, also known as selenite. In connection with these products, there were kilns at the

mineral mill where the various minerals were calcined or burnt.

Between 1896 and 1902 Buxton Lime Firms moved from Marple Lime Works to Rose Hill and this implies that Marple Lime Works was still operative in 1896 and that by 1902 it had closed down.

The Tymm Family

Early references to the Tymm family occur at Ludworth, which was a hamlet in the Mellor Parish of the Glossop Union. Ludworth was included with

Glossop Dale, Padfield, Hadfield, Dinting, Whitfield, Chunal, Simmondley, Charlesworth and Chisworth for the purpose of collecting Window Tax in the 18th century. A Primitive Methodist Chapel

was built in 1875 and there were quarries that produced wall stones and paving setts. Kelly's Trade Directory for 1891 lists no prominent members of the family living in Ludworth at this time but

there was a Joseph Tymm who was a farmer living at Mellor. Nowadays, the name of the hamlet is remembered in the name of two schools, Ludworth Primary School and Ludworth School in the Lower Fold area of Marple Bridge.

The 1861 census returns for Ludworth record the following:

Windsor Castle, Glossop Road, Ludworth, Derbyshire.

| Names | How Related | Status | Age | Occupation | Where Born |

|---|---|---|---|---|---|

| Joseph Tymm | Head | M | 47 | Beer Seller | Torkington, Ches |

| Mary Tymm | Wife | M | 51 | Ludworth, Derbys | |

| Wright Tymm | Son | Un | 23 | Bookkeeper at Lime Kilns | Do, Do |

| Jesse Tymm | Son | Un | 21 | Banksman at Coal Mine | Do, Do |

| Joseph Tymm | Son | Un | 14 | Carter | Do, Do |

| Mary Tymm | Daur | 8 | Scholar | Do, Do | |

| Sarah Crane | Boarder | Un | 17 | Power Loom Cotton Weaver | Do, Do |

Lower Fold, Ludworth, Derbyshire, 1861

Mathew Tymm, aged 70 years, is recorded at Lower Fold. He was an agricultural labourer born in Cheshire who was living with his son-in-law, William Ward, aged 35 years,

a Railway Labourer. Mathew Tymm and Joseph Tymm were living in close proximity to each other and it is likely that they were related, possibly father and son, but no corroborative evidence has been found.

The occupations of Wright and Jesse Tymm show that they were working in the mineral trade. Wright was already working at Marple Lime Works and Jesse was working at a coal mine.

Marple census returns, 1871

These show that by this time two sons of Joseph Tymm had married and were living in the Lime Kilns at Marple Lime Works.

Lime Kilns, Marple, Cheshire.

| Names | How Related | Status | Age | Occupation | Where Born |

|---|---|---|---|---|---|

| Jesse Tymm | Head | M | 31 | Lime Merchant | Ludworth, Derbys |

| Mary Tymm | Wife | M | 29 | Domestic | Mellor, Derbys |

| Lucy Tymm | Daur | 8 | Scholar | Ludworth, Derbys | |

| Jesse Tymm | Son | 5 | Scholar | Marple, Ches | |

| Matilda Tymm | Daur | 3 | Scholar | Do, Do | |

| Ellis M Tymm | Son | 1 | Do, Do |

Lime Kilns, Marple, Cheshire.

| Names | How Related | Status | Age | Occupation | Where Born |

|---|---|---|---|---|---|

| Joseph Tymm Jnr | Head | M | 24 | Engine Driver | Compstall, Derbys |

| Hannah Tymm | Wife | M | 24 | Domestic | Marple, Ches |

| Martha H Tymm | Daur | 2 | Do, Do |

Referring to the census return for Jesse and Mary Tymm, the middle name of Ellis M Tymm was Montagu; this being added after registration. In 1892 Ellis Montagu Tymm married Agnes Macgregor in the Chorlton Registration District.

Jesse Tymm (1839-1897) and his wife, Mary Middleton (1840-1911), were married in the Hayfield District in 1862. They had twelve children, these being: Lucy Ann (1862), Joseph Wright (1864-1866), Jesse (1866-1874), Matilda (1868), Ellis Montagu (1869), Mary Esther (1871), Cecil (1873), Henry (1875-1882), Robert Norman (1877), Phoebe (1879), George (1881) and Joseph (1883-1886).

Joseph Tymm Junior seems to have had two children, namely Martha Hannah (1869) and George William (1872).

Over the years, Jesse Tymm described his occupation in a variety of interesting ways:

| Date | Address | Occupation |

|---|---|---|

| 1864 | Lime Kilns, Marple | Coal Proprietor |

| 1866 | Engine Driver | |

| 1867 | Colliery Proprietor | |

| 1869 | Engine Driver | |

| 1871 | Salesman at a Canal Wharf | |

| 1873 | Salesman for a Lime Company | |

| 1875 | Lime Burner and Colliery Proprietor | |

| 1877 | Lime Burner and Colliery Proprietor | |

| 1879 | New Road, Marple | Lime Burner and Merchant |

| 1881 | Lime Kilns, Marple | Colliery Proprietor and Lime Merchant |

| 1881 | New Road, Marple | Lime Burner |

| 1883 | Mineral Mill House, Marple | Colliery Proprietor and Lime Merchant |

An examination of the above table shows that Jesse Tymm was a coal proprietor by 1864 and this is corroborated in 1867. In 1875 he stated that he was a lime burner and colliery proprietor and this suggests that by this time he had taken full control of the lime kilns. This is corroborated in subsequent years and by 1883 he had moved into Mineral Mill House adjacent to Marple Mineral Mill. Thus, he operated the collieries that supplied him with coal as well as the manufacturing process to produce burnt lime and as a merchant he was able to distribute the finished produce as well.

Marple census returns, 1881

These record that Wright Tymm was living in Matt Street, Off Pump Street, Marple, where he was described as a lime burner.

| Names | How Related | Status | Age | Occupation | Where Born |

|---|---|---|---|---|---|

| Wright Tymm | Head | Widower | 43 | Lime Burner | Ludworth, Derbys |

| Mary Ratcliffe Tymm | Daur | 12 | Scholar | Marple, Ches | |

| Harriet A Tymm | Daur | 11 | Scholar | Do, Do | |

| Mary Ratcliffe | Aunt | Un | 60 | Housekeeper | Mellor, Derbys |

Wright Tymm (1837-1904) and his wife, Harriet Ratcliffe, were married in the Hayfield District in 1868. Harriet died in 1870, aged 23 years, and this coincides with the birth of their daughter, Harriet Ann Tymm. Wright never remarried.

Marple census returns, 1881

These record that Joseph Tymm was recorded living at the Mineral Mill, Marple, where he was described as a farmer. It is considered that this was a census error and that he was actually living in the

house next door to the mill

| Names | How Related | Status | Age | Occupation | Where Born |

|---|---|---|---|---|---|

| Joseph Tymm | Head | M | 34 | Farmer | Compstall, Derbys |

| Hannah M Tymm | Wife | M | 34 | Farmer's Wife | Marple, Ches |

| Martha H Tymm | Daur | 12 | Scholar | Do, Do | |

| George W Tymm | Son | 8 | Scholar | Do, Do | |

| Mary Tymm | Daur | 5 | Scholar | Marple Bridge, Ches |

Marple census returns, 1901

These record that Wright Tymm was living at Roselegh, Stockport Road, Marple, where he was described as a brickmaker employer.

The Tymm family were connected with the Jinks family of Marple boat builders when Mary Tymm, the daughter of Joseph and Mary Tymm married Richard Jinks, son of James Jinks, at All Saints, Marple, in 1870.

The senior members of the family, Joseph and Mary Tymm, along with several members of their family, were laid to rest in the graveyard of All Saints, Marple:

| Names | How Related | Status | Age | Occupation | Where Born |

|---|---|---|---|---|---|

| Wright Tymm | Head | Widower | 63 | Brickmaker | Ludworth, Derbys |

| Harriet A Todd | Daur | M | 31 | Marple, Ches | |

| William W Todd | Son-in-L | M | 31 | Russia | |

| Wright J D Todd | Gson | S | 4 | Marple, Ches | |

| Mary M I Todd | Gdaur | S | 1 | Do, Do | |

| Mary Ratcliffe | Aunt | S | 80 | Mellor, Derbys | |

| Mary Williams | Servant | S | 17 | Domestic Servant | Brimlo?, Ches |

| Emily Olsten | Nurse | S | 12 | Domestic Servant | Bollington, Ches |

At the time that the brick works was founded, the Tymms built two houses by the works entrance. On completion of these, Wright Tymm moved into one of them, which he named Roselegh.

Discovery of a Tymm brick

In Dec 2008, a British Waterways maintenance team were excavating the sidepond of Lock 4 of the Bosley flight of locks on the Macclesfield Canal. The work required the excavation of vertical shaft, of

stone construction, and a horizontal culvert, also constructed of stone, but having a brick arch or turn. Among the rubble removed from the shaft there was an unused brick with TYMMS MARPLE incised in the frog.

The importance of the discovery of an unused brick manufactured by J & M Tymm of the Rose Hill Brick Works, Marple, was immediately recognised. Staircase House, Market Place, Stockport, has on display another example of a brick manufactured by this company. Additionally, another two similar bricks on display are likely to have been manufactured by J & M Tymm. One is marked 'Rose Hill' and the other is marked 'Middlewood'.

Brick manufactured by J & M Tymm.

Credit: D Kitching.

Marple Corn/Mineral Mill

The building next door to the lime works was let by Samuel Oldknow as a corn mill and a tithe map of 1850 shows that by then all the land, including that on which the

lime works and mill stood, was owned by Peter Arkwright of Cromford. The mill was described as a 'corn mill and house' without an occupier but the adjoining house was occupied by Henry Harris.

Over the period that the mill was operating as a corn mill it is understood that it was powered by a 25hp steam engine and that the miller in the early to mid-19th century was Francis Brindley & Co.

It is on record that around the mid-19th century there was a slump in corn milling and some corn mills were going out of business; a nearby example being Arden Mill in Bredbury.

The history of the corn/mineral mill is now examined in more detail.

On account of financial difficulties, the Peak Forest Canal Company was unable to proceed with the construction of Marple Locks. By as early as 1797, these difficulties were impeding the company's trading capability, so the Committee resolved to bypass the unfinished locks with a single-track tramway of similar design to the Peak Forest Tramway. Work on constructing this commenced in January 1798 and in the meantime the company was negotiating a loan from Richard Arkwright Junior of Willersley Castle, Cromford, Derbyshire, in order to complete the locks. The higher terminus of this tramway was hard by Brick Change Bridge on the Upper Peak Forest Canal. A short distance before the bridge the summit warehouse was built, to facilitate the transhipment of goods, and between the warehouse and the bridge a waggon-loading wharf was provided. It is considered that the summit warehouse was the origin of Samuel Oldknow's corn mill and that when the tramway closed in February 1807 he was responsible for its conversion to this new purpose.

Samuel Oldknow was invariably in financial difficulties, as a consequence of which he was in substantial debt to the Arkwright family. To all intents and purposes Oldknow was bankrupt and the Arkwrights kept him solvent. At the time of Oldknow's death in 1828, the whole of his estates became the property of the Arkwright family in settlement. The outcome of this was that all the land and buildings thereon connected with Marple Lime Works and Mill henceforth belonged to the Arkwright family.

Ashworth and Oldham researched the early years of the corn mill and on the 12 Apr 1850 an advertisement appeared in the Stockport Advertiser offering the corn mill for let. This advertisement corroborated the Brindley connection by stating that the present occupiers, Francis Brindley & Co, were moving their business to Macclesfield. Apparently nothing came of this and in 1853 it was re-advertised when it was still occupied by Francis Brindley & Co. Also to let were a good dwelling house ('Bleak House'), stable, cow house gig house (for the storage of carts) and other outbuildings. It was stated that the mill might, with inconsiderable outlay, be converted to a manufacturing process and in the event this is what happened.

Francis Brindley died on the 27 Apr 1834, aged 63 years, and it was his youngest son, Robert, who took control of the corn-milling business. It seems that Marple Corn Mill was to let because the company wanted to consolidate its business at the Steam Mills on Union Road, Macclesfield, by the side of the Macclesfield Canal. Subsequently, the Macclesfield business became Samuel Fitton & Sons and then Hovis.

By 1858, the Marple business was known as the Marple Mills Mineral Co, which confirms a change of use, the proprietor being John Walker Goodall. However, he died prematurely in Stockport in 1859, aged 33 years. Peter Arkwright then leased the business to John Ryde and William Singleton Birch of Manchester for a period of 21 years. By 1864 the company manager was John Worthington and the company occupied a wharf in Sackville Street on the Rochdale Canal. The following year the company had two wharfs in Manchester, one in Oxford Road on the Rochdale Canal and another in London Road on the Ashton Canal. Ryde and Birch continued to run the mineral mill until 1880 when their lease expired. The company's manager from c.1870 until 1880 was John Platt. William Singleton Birch died in 1888, aged 66 years, and his death was registered in Barrow on Soar, Leicestershire. In 1887/88 the business was purchased by the Tymm family who, by this time, were operating the lime works next door. The occupancy of the mineral mill between 1880 and 1887/88 is obscure.

Klondike Brick Works & the Tymm family

The date at which the Tymm family established their brick works at Rose Hill, Marple, near Rose Hill railway station is unclear. A company advertisement for 1883 shows that by this time the company was

marketing blue, red and fire bricks. It is recognised that the company manufactured red bricks (customarily known as common or building bricks) but there is no evidence that blue engineering bricks or fire bricks were

ever manufactured at Rose Hill. It is possible that the company bought these in from elsewhere to resell. The date of 1883 can be compared and contrasted with an Ordnance Survey map of c.1875 that shows that the

land upon which the brick works was built was still a field at this time.

The company’s head office was in Marple and they opened a depot on Store Street, off London Road, Manchester. The Tymms were also the last to control Marple Lime Works and Mineral Mill and perhaps they were the most effective at managing the business.

Left: Klondike Brick Works at Rose Hill is in the background on the right, identified by the tall chimney, and Rose Hill Station is in the foreground, early 20th century.

Right: Map of the Klondike Brick Works at Rose Hill, 1909.

Competition between rival Lime Firms

By 1891 the intense competition between lime firms, all of whom were dependent upon the limestone quarries at Dove Holes, had come to a head. The effect of this was to force prices down to a level that was

uneconomic and as a result of this thirteen independent companies, of which the J & M Tymm business was one, amalgamated to form Buxton Lime Firms Company Ltd (BLF). This enabled trading to continue into the

20th century. Concerning the company name of J & M Tymm, the ‘M’ stands for ‘Montagu’ who was the third son of Jesse Tymm. His birth in 1869 was registered as

Ellis Tymm and ‘Montagu’ was added as a middle name after the registration of his birth. Apart from the record of his marriage, as Ellis Montagu Tymm in 1892, no other details about him have been

discovered and his name does not appear in trade directories either. Despite this, the 1901 census shows that Wright Tymm was still actively involved in the business because he described himself as Brickmaker Employer.

The formation of BLF extended the life of the Tymm lime-burning business for a while but in c.1902 Marple Lime Works and Mineral Mill closed. An Ordnance Survey map of 1910 marks both the lime works and mineral mill as being disused. Notwithstanding this, families continued to use the dwellings in the kilns for a while afterwards. The last known inhabitant was Albert Aldred, a cotton mill labourer, and his family in 1931.

The demise of Marple Lime Works and Mineral Mill did not spell the end of the brick works at Rose Hill. This continued in business until the 1920s when it too closed.

In 1918, the Cheshire chemical firm of Brunner Mond & Co, based at Northwich, bought a controlling interest in BLF and this was converted to total ownership in 1926. Following this, the businesses merged to form Imperial Chemical Industries Ltd.

Acknowledgements

Stockport Heritage Library for sources of information.

Staircase House, Stockport, for information about their collection of Tymm bricks.

The former British Waterways for discovering the unused Tymm brick and in recognising its archaeological importance.

Manchester Central Library, Manchester Archives and Local Studies Section, for sources of information.

N Brindley for information about the mill being powered by a steam engine when it was operational as a corn mill and that the millers around this time were his antecedents, Francis and Robert Brindley.

Further Reading

Historic Industries of Marple and Mellor. Originally produced by members of the Marple Branch of the Workers' Educational Association, edited by Professor Owen Ashmore, MA, revised and updated by

Ann Ashworth and Tom Oldham, (1989).