The National Coal Mining Museum for England is situated on New Road, Overton, Wakefield, Yorkshire, WF4 4RH.

Caphouse Colliery (formerly Overton Colliery) opened in c.1790 to work the Flockton Thick Mine and Flockton Thin Mine. It closed in 1985 and was then redeveloped as a mining museum. Firstly as the Yorkshire Mining Museum (1988) and then as the National Coal Mining Museum (1995) after the closure of the Chatterley Whitfield Colliery Museum in North Staffordshire on the 9 Aug 1993. It ncorporates three sites, Caphouse Colliery, Hope Pit and the Inman Water Shaft.

|

|

Caphouse Colliery headgear. |

Winding House. The preserved winding engine was built by Davy Brothers of Sheffield in 1876. It is a twin cylinder slide valve engine with 16-inch diameter cylinders and a stroke of 3 feet. Its nominal speed is 60 revolutions per minute. |

|

|

Winding House. The winding drum is 9 feet diameter. Note the timber cladding on the cylinder in the foreground. |

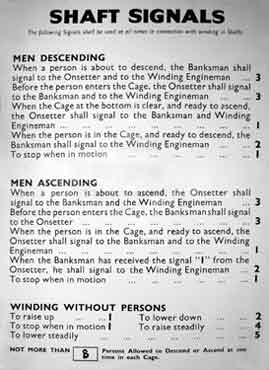

Winding House. Notice about shaft signals when winding. |

|

Datestone above the door of the Winding House. The initials ‘ELK’ on the datestone commemorate Emma Lister-Kaye She was resident at Overton Lodge close to the colliery and she founded schools near Denby Grange and supported the church and schools at Middlestown. |

|

|

Lamp Room. Where safety lamps were issued to miners going on shift. |

Coal Tub. |

|

|

Screen Building. Where coal was graded in preparation for sale. |

Where coal waggons were loaded. |

|

Lancashire Boilers. Two coal-fired boilers were installed and these were fitted with 'Low Ram' mechanical stokers manufactured by John Hodgkinson (Salford) Ltd of Salford, Lancashire. |

|

|

Pithead Baths. Entrance to the locker room where clothes were stored. |

Pithead Baths locker room. |

|

|

Pithead Baths shower room. |

Pit Ponies Ernie and Eric. |

|

Pit Cat. |

|

|

Hope Pit. This pit is situated about 593 yards south west of Caphouse Colliery. Sir John Lister-Kaye, owner of Caphouse Colliery, appointed John Blenkinsop, a mining engineer, as the consultant and the shaft was sunk to a depth of 215 yards in 1827/29. Later this was deepened to the New Hards Mine. This pit was one of the earliest in Yorkshire to use electrical coal cutters. A mineral railway from Caphouse Colliery and Hope Pit was constructed that passed under the adjacent road via the Lister-Kaye tunnel. Coal waggons could then travel to Calder Grove to join the main line railway and the Calder and Hebble Navigation. |

Inman Pumping Engine House. This was built near Hope Pit in c.1841 to house a beam engine employed to pump water from the mine workings by means of the Inman Water Shaft sunk to a depth of 97 yards. It is understood that the original pump was a Cornish pumping engine. |

Listing

The winding house, heapstead* and headstock (headgear) is listed Grade II*, List Entry No. 1135482.

The boiler house and chimney is listed Grade II, List Entry No. 1135481.

Wooden headgear and associated spoil heap, about 250 yards north west of Caphouse Colliery, is a Scheduled Ancient Monument, List Entry No. 1013407.

Coal Mining Museums